Jeep Cherokee (XJ): Disassembly and assembly. Cleaning and inspection. Specifications

CYLINDER BLOCK DISASSEMBLY Refer to the applicable sections for detailed

instructions.

(1) Drain the engine oil. Remove and discard the

oil filter.

(2) Remove the water pump from the cylinder

block.

(3) Remove the vibration damper.

(4) Remove the timing case cover and lay the cover

upside down.

(5) Position a drift punch into the slot in the back

of the cover and tap the old seal out.

(6) Remove the oil slinger from crankshaft.

(7) Remove the camshaft retaining bolt and

remove the sprockets and chain as an assembly.

(8) Remove the camshaft.

(9) Remove the oil pan and gasket.

(10) Remove the front and rear oil galley plugs.

(11) Remove the oil pump.

(12) Remove the connecting rods and the pistons.

Remove the connecting rod and piston assemblies

through the top of the cylinder bores.

(13) Remove the crankshaft. ASSEMBLY Refer to the applicable sections for detailed

instructions.

(1) Install the crankshaft.

(2) Install the connecting rods and the pistons

through the top of the cylinder bores.

(3) Install the oil pump.

(4) Install the oil pan and gasket.

(5) Install the camshaft.

(6) Install the sprockets and chain as an assembly.

(7) Install the oil slinger from the crankshaft.

(8) Install the timing case cover seal.

(9) Install the timing case cover.

(10) Install the vibration damper.

(11) Install the water pump. Tighten the mounting

bolts to 31 N·m (23 ft. lbs.) torque. (12) Lubricate the oil filter seal with clean engine

oil. Tighten oil filter to 18 N·m (156 in. lbs.) torque.

(13) Install the engine into the vehicle.

(14) Fill the engine with clean lubrication oil (refer

to Group 0, Lubrication and Maintenance).

(15) Fill the cooling system. CLEANING Thoroughly clean the engine cylinder head and cylinder

block mating surfaces. Clean the intake and

engine exhaust manifold and engine cylinder head

mating surfaces. Remove all gasket material and carbon.

Check to ensure that no coolant or foreign material

has fallen into the tappet bore area.

Remove the carbon deposits from the combustion

chambers and top of the pistons. INSPECTION Use a straightedge and feeler gauge to check the

flatness of the engine cylinder head and block mating

surfaces. CLEANING Remove any original sealer from the cover sealing

surface of the engine cylinder head and clean the

surface using a fabric cleaner.

Remove all residue from the sealing surface using

a clean, dry cloth. INSPECTION Inspect the engine cylinder head cover for cracks.

Replace the cover, if cracked.

The original dark grey gasket material should

NOT be removed. If sections of the gasket material

are missing or are compressed, replace the engine

cylinder head cover. However, sections with minor

damage such as small cracks, cuts or chips may be

repaired with a hand held applicator. The new material

must be smoothed over to maintain gasket

height. Allow the gasket material to cure prior to

engine cylinder head cover installation. CLEANING Clean all the components with cleaning solvent.

Use compressed air to blow out the oil passages in

the rocker arms and push rods. INSPECTION Inspect the pivot surface area of each rocker arm.

Replace any that are scuffed, pitted, cracked or

excessively worn.

Inspect the valve stem tip contact surface of each

rocker arm and replace any rocker arm that is deeply

pitted.

Inspect each push rod end for excessive wear and

replace as required. If any push rod is excessively

worn because of lack of oil, replace it and inspect the

corresponding hydraulic tappet for excessive wear.

Inspect the push rods for straightness by rolling

them on a flat surface or by shining a light between

the push rod and the flat surface.

A wear pattern along the length of the push rod is

not normal. Inspect the engine cylinder head for

obstruction if this condition exists. CLEANING Clean each tappet assembly in cleaning solvent to

remove all varnish, gum and sludge deposits. INSPECTION Inspect for indications of scuffing on the side and

base of each tappet body.

Inspect each tappet base for concave wear with a

straightedge positioned across the base. If the base is

concave, the corresponding lobe on the camshaft is

also worn. Replace the camshaft and defective tappets.

After cleaning and inspection, test each tappet for

specified leak-down rate tolerance to ensure zero-lash

operation (Fig. 84).

Swing the weighted arm of the hydraulic valve tappet

tester away from the ram of the Leak-Down

Tester.

(1) Place a 7.925-7.950 mm (0.312-0.313 inch)

diameter ball bearing on the plunger cap of the tappet.

(2) Lift the ram and position the tappet (with the

ball bearing) inside the tester cup.

(3) Lower the ram, then adjust the nose of the ram

until it contacts the ball bearing. DO NOT tighten

the hex nut on the ram.

(4) Fill the tester cup with hydraulic valve tappet

test oil until the tappet is completely submerged.

(5) Swing the weighted arm onto the push rod and

pump the tappet plunger up and down to remove air.

When the air bubbles cease, swing the weighted arm

away and allow the plunger to rise to the normal

position.

(6) Adjust the nose of the ram to align the pointer

with the SET mark on the scale of the tester and

tighten the hex nut. (7) Slowly swing the weighted arm onto the push

rod.

(8) Rotate the cup by turning the handle at the

base of the tester clockwise one revolution every 2

seconds.

(9) Observe the leak-down time interval from the

instant the pointer aligns with the START mark on

the scale until the pointer aligns with the 0.125

mark. A normally functioning tappet will require

20-110 seconds to leak-down. Discard tappets with

leak-down time interval not within this specification.

1 - POINTER CLEANING Thoroughly clean the oil pan and engine block gasket

surfaces. Use compressed air to clean out: Once the block has been completely cleaned, apply

Loctite PST pipe sealant with Teflon 592 to the

threads of the front and rear oil galley plugs. Tighten

the plugs to 34 N·m (25 ft. lbs.) torque. INSPECTION (1) It is mandatory to use a dial bore gauge to

measure each cylinder bore diameter (Fig. 85). To

correctly select the proper size piston, a cylinder bore

gauge, capable of reading in 0.003 mm (.0001 in.)

INCREMENTS is required. If a bore gauge is not

available, do not use an inside micrometer.

(2) Measure the inside diameter of the cylinder

bore at three levels below top of bore. Start perpendicular

(across or at 90 degrees) to the axis of the

crankshaft and then take two additional reading.

(3) Measure the cylinder bore diameter crosswise

to the cylinder block near the top of the bore. Repeat

the measurement near the middle of the bore, then

repeat the measurement near the bottom of the bore.

(4) Determine taper by subtracting the smaller

diameter from the larger diameter.

(5) Rotate measuring device 90 and repeat steps

above.

(6) Determine out-of-roundness by comparing the

difference between each measurement.

(7) If cylinder bore taper does not exceed 0.025

mm (0.001 inch) and out-of-roundness does not

exceed 0.025 mm (0.001 inch), the cylinder bore can

be honed. If the cylinder bore taper or out- of-round

condition exceeds these maximum limits, the cylinder

must be bored and then honed to accept an oversize

piston. A slight amount of taper always exists in the

cylinder bore after the engine has been in use for a

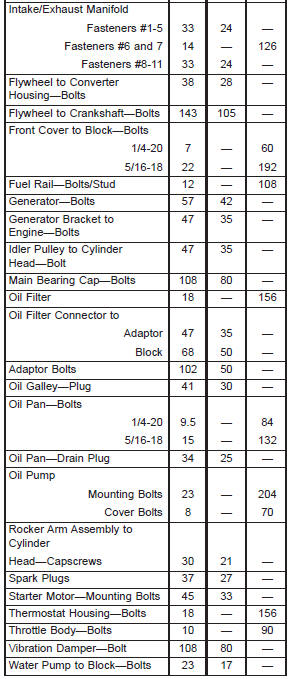

period of time. Specifications 4.0L ENGINE

Torque specifications 4.0L ENGINE

Disassembly and assembly

Cleaning and inspection

Cylinder head

Cylinder head cover

Rocker arms and push rods

Hydraulic tappets

Fig. 84 Leak-Down Tester

2 - WEIGHTED ARM

3 - RAM

4 - CUP

5 - HANDLE

6 - PUSH RODCylinder block

Fig. 85 Cylinder Bore MeasurementSpecifications

Crankshaft oil seals-rear. Oil pump. Timing case cover oil seal

Crankshaft oil seals-rear. Oil pump. Timing case cover oil seal

Other materials:

Power steering

Description and operation

STEERING SYSTEM

DESCRIPTION

The power steering system has a hydraulic pump.

The pump is a constant flow rate and displacement,

vane-type pump. The pump on the 4.0L engine has a

reservoir mounted to it (Fig. 1). The 2.5L engine has

a remote mounted reservoir.

The ...