Jeep Cherokee (XJ): Service procedures

When an air conditioning system is assembled at

the factory, all components except the compressor are

refrigerant oil free. After the refrigerant system has

been charged and operated, the refrigerant oil in the

compressor is dispersed throughout the refrigerant

system. The accumulator, evaporator, condenser, and

compressor will each retain a significant amount of

the needed refrigerant oil.

It is important to have the correct amount of oil in

the refrigerant system. This ensures proper lubrication

of the compressor. Too little oil will result in

damage to the compressor. Too much oil will reduce

the cooling capacity of the air conditioning system.

It will not be necessary to check the oil level in the

compressor or to add oil, unless there has been an oil

loss. An oil loss may occur due to a rupture or leak

from a refrigerant line, a connector fitting, a component,

or a component seal. If a leak occurs, add 30

milliliters (1 fluid ounce) of refrigerant oil to the

refrigerant system after the repair has been made.

Refrigerant oil loss will be evident at the leak point

by the presence of a wet, shiny surface around the

leak.

Refrigerant oil must be added when a accumulator,

evaporator coil, or condenser are replaced. See the

Refrigerant Oil Capacities chart. When a compressor is replaced, the refrigerant

oil must be drained from

the old compressor and measured. Drain all of the

refrigerant oil from the new compressor, then fill the

new compressor with the same amount of refrigerant

oil that was drained out of the old compressor.

WARNING: REVIEW THE WARNINGS AND CAUTIONS

IN THE GENERAL INFORMATION SECTION

NEAR THE FRONT OF THIS GROUP BEFORE

RECOVERING REFRIGERANT.

A R-134a refrigerant recovery/recycling/charging

station that meets SAE Standard J2210 must be

used to recover the refrigerant from an R-134a refrigerant

system. Refer to the operating instructions supplied

by the equipment manufacturer for the proper

care and use of this equipment. WARNING: REVIEW THE WARNINGS AND CAUTIONS

IN THE GENERAL INFORMATION SECTION

NEAR THE FRONT OF THIS GROUP BEFORE EVACUATING

THE SYSTEM.

If the refrigerant system has been open to the

atmosphere, it must be evacuated before the system

can be charged. If moisture and air enters the system

and becomes mixed with the refrigerant, the compressor

head pressure will rise above acceptable

operating levels. This will reduce the performance of

the air conditioner and damage the compressor.

Evacuating the refrigerant system will remove the

air and boil the moisture out of the system at near

room temperature. To evacuate the refrigerant system,

use the following procedure:

(1) Connect a R-134a refrigerant recovery/recycling/

charging station that meets SAE Standard

J2210 and a manifold gauge set to the refrigerant

system of the vehicle.

(2) Open the low and high side valves and start

the charging station vacuum pump. When the suction

gauge reads 88 kPa (26 in. Hg.) vacuum or

greater, close all of the valves and turn off the vacuum

pump.

(a) If the refrigerant system fails to reach the

specified vacuum, the system has a leak that must

be corrected. See Refrigerant System Leaks in the

Diagnosis and Testing section of this group for the

procedures.

(b) If the refrigerant system maintains the specified

vacuum for five minutes, restart the vacuum

pump, open the suction and discharge valves and

evacuate the system for an additional ten minutes.

(3) Close all of the valves, and turn off the charging

station vacuum pump.

(4) The refrigerant system is now ready to be

charged with R-134a refrigerant. See Refrigerant

System Charge in the Service Procedures section of

this group. WARNING: REVIEW THE WARNINGS AND CAUTIONS

IN THE FRONT OF THIS GROUP BEFORE

CHARGING THE REFRIGERANT SYSTEM.

After the refrigerant system has been tested for

leaks and evacuated, a refrigerant charge can be

injected into the system. See Refrigerant Charge

Capacity for the proper amount of the refrigerant

charge.

A R-134a refrigerant recovery/recycling/charging

station that meets SAE Standard J2210 must be

used to charge the refrigerant system with R-134a

refrigerant. Refer to the operating instructions supplied

by the equipment manufacturer for proper care

and use of this equipment. REFRIGERANT CHARGE CAPACITY The R-134a refrigerant system charge capacity for

this vehicle is 0.567 kilograms (1.25 pounds). WARNING: EYE PROTECTION MUST BE WORN

WHEN SERVICING AN AIR CONDITIONING REFRIGERANT

SYSTEM. TURN OFF (ROTATE CLOCKWISE)

ALL VALVES ON THE EQUIPMENT BEING USED,

BEFORE CONNECTING TO OR DISCONNECTING

FROM THE REFRIGERANT SYSTEM. FAILURE TO

OBSERVE THESE WARNINGS MAY RESULT IN PERSONAL

INJURY.

When servicing the air conditioning system, a

R-134a refrigerant recovery/recycling/charging station

that meets SAE Standard J2210 must be used.

Contact an automotive service equipment supplier for

refrigerant recovery/recycling/charging equipment.

Refer to the operating instructions supplied by the equipment manufacturer for

proper care and use of

this equipment.

A manifold gauge set may be needed with some

recovery/recycling/charging equipment (Fig. 13). The

service hoses on the gauge set being used should

have manual (turn wheel), or automatic back-flow

valves at the service port connector ends. This will

prevent refrigerant from being released into the

atmosphere.

1 - HIGH PRESSURE GAUGE MANIFOLD GAUGE SET CONNECTIONS CAUTION: Do not use an R-12 manifold gauge set

on an R-134a system. The refrigerants are not compatible

and system damage will result.

LOW PRESSURE GAUGE HOSE The low pressure

hose (Blue with Black stripe) attaches to the suction

service port. This port is located on the suction line

between the accumulator outlet and the compressor.

HIGH PRESSURE GAUGE HOSE The high pressure

hose (Red with Black stripe) attaches to the discharge

service port. This port is located on the

discharge line between the compressor and the condenser

inlet.

RECOVERY/RECYCLING/EVACUATION/CHARGING

HOSE The center manifold hose (Yellow, or

White, with Black stripe) is used to recover, evacuate,

and charge the refrigerant system. When the low

or high pressure valves on the manifold gauge set

are opened, the refrigerant in the system will escape

through this hose.Refrigerant oil level

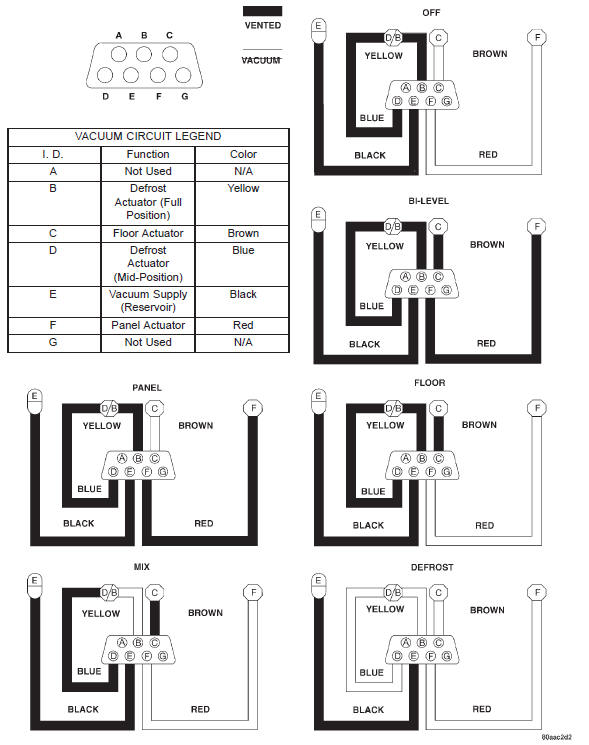

Fig. 11 Vacuum Circuits - Heater Only

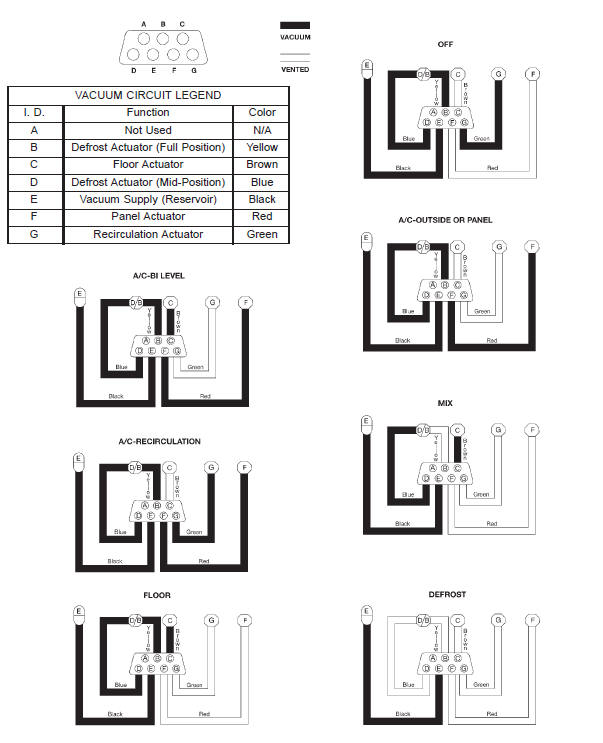

Fig. 12 Vacuum Circuits - Heater-A/C

Refrigerant recovery

Refrigerant system evacuate

Refrigerant system charge

Refrigerant system service

equipment

Fig. 13 Manifold Gauge Set - Typical

2 - VALVE

3 - VACUUM/REFRIGERANT HOSE (YELLOW W/BLACK

STRIPE)

4 - HIGH PRESSURE HOSE (RED W/BLACK STRIPE)

5 - LOW PRESSURE HOSE (BLUE W/BLACK STRIPE)

6 - VALVE

7 - LOW PRESSURE GAUGE

Low pressure cycling clutch switch. Refrigerant system leaks. Vacuum system

Low pressure cycling clutch switch. Refrigerant system leaks. Vacuum system

Other materials:

Powertrain control module (PCM)

DESCRIPTION

The Powertrain Control Module (PCM) is located

in the engine compartment (Fig. 1). The PCM is

referred to as JTEC.

OPERATION

The PCM operates the fuel system. The PCM is a

pre-programmed, triple microprocessor digital computer.

It regulates ignition timing, air-fuel ratio,

emis ...